The question of whether a hydraulic pump can generate pressure is fundamental to understanding the core function of a hydraulic system. In fact, hydraulic pumps play a key role in converting mechanical energy into hydraulic energy, thereby creating pressure within the fluid. These devices are designed to suck in hydraulic fluid and apply force to push it through the system, creating the pressure that powers a variety of machinery and equipment. Whether utilizing a reciprocating piston pump or a gear pump that relies on rotating gears, hydraulic pumps are designed to generate the force required for the efficient operation of a hydraulic system.

1. Working principle of hydraulic pump

2. Type of hydraulic pump that generates pressure

3. Factors affecting pressure generation in hydraulic systems

1. Working principle of hydraulic pump

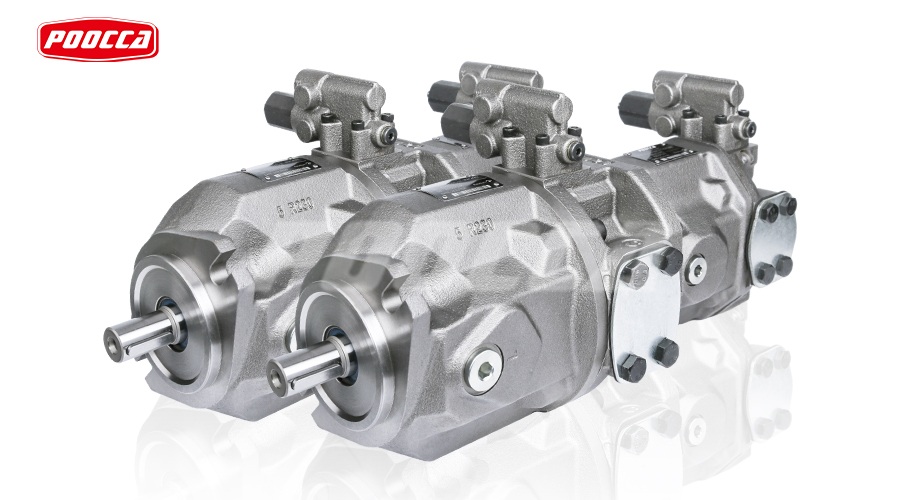

A hydraulic pump is an important component in a hydraulic system, its key function is to generate pressure to drive fluid through the system. Their versatility allows them to power a wide range of machinery and equipment, playing a key role in industries such as manufacturing, construction and transportation. Here we explore two common hydraulic pumps that excel at pressure generation:

1. Piston pump:

Piston pumps are widely recognized for their efficiency in generating high pressure in hydraulic systems. They work on the principle of reciprocation, where the piston moves back and forth within the cylinder. When the piston retracts, a vacuum is created that draws hydraulic oil into the cylinder. Then, as the piston extends, it pressurizes the fluid, forcing it through the pump outlet and into the hydraulic system.

One of the main advantages of piston pumps is their ability to generate sufficient pressure levels, making them suitable for applications requiring high forces, such as heavy industrial machinery and hydraulic presses. In addition, variable displacement piston pumps can adjust the output flow to flexibly manage pressure levels according to the specific requirements of the application.

2. Gear pump:

Gear pumps are another popular type of hydraulic pump known for their simplicity and reliability. They consist of two meshing gears – a driving gear and a driven gear – mounted inside the pump casing. As the gears rotate, they create chambers that draw in hydraulic fluid at the pump inlet. The rotation then forces the fluid into the outlet, creating the pressure needed to operate the hydraulic system.

While gear pumps may not achieve the same high-pressure levels as piston pumps, they excel in applications that require a constant and stable flow of fluid. Its compact design, low cost and minimal maintenance make it suitable for a variety of industrial applications, including material handling equipment, steering systems and hydraulic power units.

The choice of piston pump and gear pump depends on the specific requirements of the hydraulic system. Piston pumps are favored in applications requiring high pressure and variable flow, while gear pumps are valued for their simplicity, reliability and cost-effectiveness in applications where continuous and uniform flow is critical. Continuous advancements in hydraulic pump technology continue to improve the performance of these critical components, driving efficiency and innovation across different industries.

2. Type of hydraulic pump that generates pressure

A hydraulic pump is an energy conversion device that converts mechanical energy into liquid pressure energy. Its working principle is to use the change of closed volume to transport liquid, and rely on the principle of volume change to achieve work. Hydraulic pumps all work based on the principle of seal volume change, so they are also called positive displacement hydraulic pumps.

Hydraulic pumps are divided into gear type, vane type, plunger type and other types according to their structure. They each have their own characteristics, but work on the same principle. The output flow of the hydraulic pump can be adjusted as needed to meet the requirements of different working conditions.

When the hydraulic pump is working, it rotates under the driving of the prime mover, causing the working volume to continuously change, thus forming the process of oil suction and oil discharge. The flow rate of the hydraulic pump depends on the volume change value of the working chamber and the number of changes per unit time, and has nothing to do with the working pressure and the conditions of the suction and discharge pipelines.

3. Factors affecting pressure generation in hydraulic systems

The generation of pressure in hydraulic systems is affected by many factors. Here are some of the main factors:

**Load size: The greater the load of the hydraulic system, the higher the pressure that needs to be generated. The load can be the weight of a mechanical component, friction, or other resistance.

**Viscosity of oil: The viscosity of oil affects its flow rate and flow characteristics in pipelines. High viscosity oil will slow down the flow rate and increase pressure loss, while low viscosity oil will speed up the flow rate and reduce pressure loss.

**Pipe Length and Diameter: The length and diameter of the pipe affects the distance and flow of oil in the system. Longer pipes and smaller diameters increase pressure losses, thereby reducing pressure in the system.

**Valves and accessories: Valves and other accessories (such as elbows, joints, etc.) can block the flow of oil, causing increased pressure loss. Therefore, when selecting and using these components, attention should be paid to their impact on system performance.

**Leaks: Any leaks in the system will reduce the available pressure as leaks cause oil loss and reduce the pressure in the system. Therefore, it is crucial to regularly inspect and maintain your system to prevent leaks.

**Temperature changes: Temperature changes can affect the viscosity and flow characteristics of oil. Higher temperatures increase the viscosity of the oil, which increases pressure losses; while lower temperatures thin the oil, which decreases pressure losses. Therefore, the effects of temperature should be considered when designing and operating hydraulic systems.

**Pump Performance: The hydraulic pump is a key component in the system that generates pressure. The performance of the pump (such as displacement, operating pressure range, etc.) directly affects the pressure generating capacity of the system. Choosing the right pump for your system’s needs is critical to ensuring proper system operation.

**Accumulators and Pressure Control Valves: Accumulators and pressure control valves can be used to regulate the pressure levels in a system. By adjusting these components, effective control and management of system pressure can be achieved.

The generation of pressure in hydraulic systems is affected by many factors. In order to ensure the normal operation and efficient performance of the system, designers and operators need to consider these factors and take corresponding measures for optimization and management.

The clear answer to the question posed at the beginning is yes – the hydraulic pump is indeed the primary tool for generating pressure in a hydraulic system. Their role in converting mechanical energy into hydraulic power is integral in many industries, from manufacturing and construction to aerospace and automotive. Continuous advances in hydraulic pump technology continue to refine and optimize pressure generation, resulting in more efficient and sustainable hydraulic systems. As the industry evolves, hydraulic pumps remain unwavering in their importance in providing the necessary power for countless applications, underscoring their status as an essential component in the machinery of the modern world.

Post time: Dec-06-2023