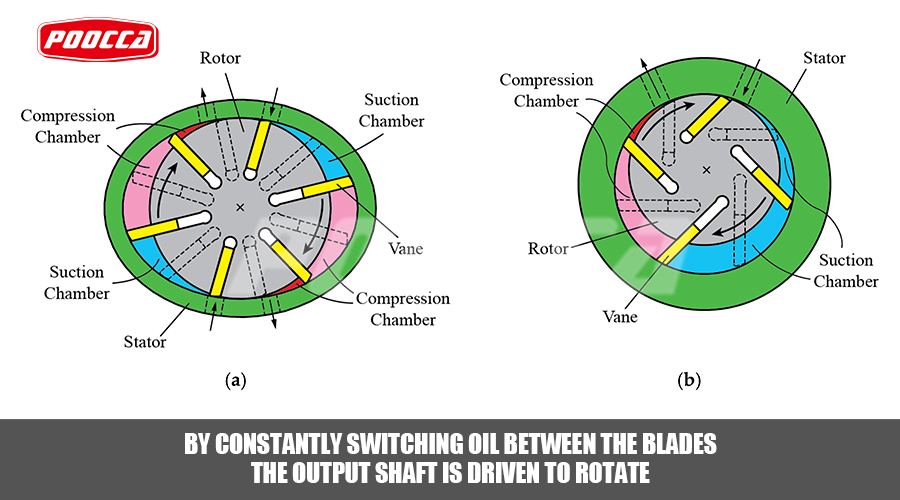

The working principle of hydraulic vane motors is mainly based on Pascal’s law. When high-pressure liquid enters the blade grooves of the motor, the blades are acted upon by the hydraulic force and generate torque. The blades rotate around the motor’s rotor shaft, thereby outputting mechanical energy. The flow of liquid between the blade grooves and the motor housing realizes the transfer of energy. Poocca has a variety of hydraulic vane motors for you to choose from.

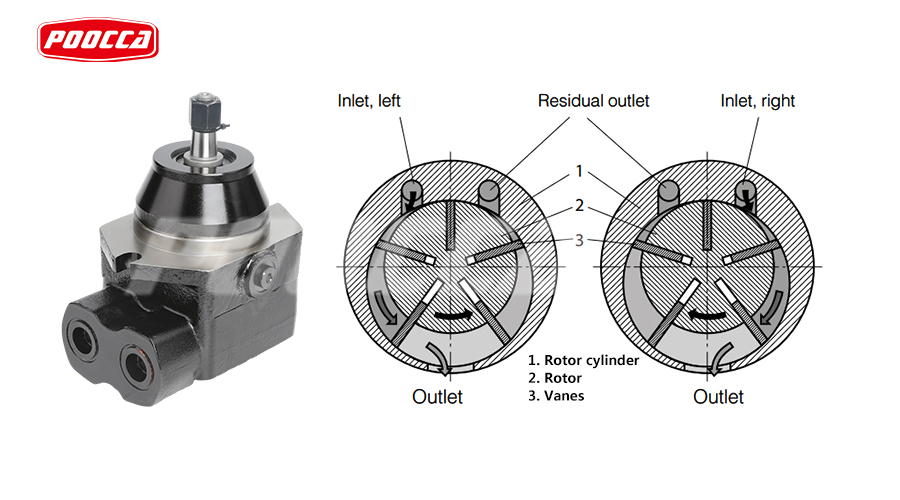

— Components of hydraulic vane motor

The hydraulic vane motor mainly consists of the following parts: housing, rotor, blades, end cover, and seals.

Housing: The housing is the basic structure of the motor and is used to contain hydraulic fluid and protect internal parts.

Rotor: The rotor is the core component of the motor and cooperates with the blades to achieve energy conversion. The rotor is usually a hollow shaft structure with spiral grooves inside to guide the flow of hydraulic oil.

Blade: The blade is a key component that cooperates with the rotor. Its shape and material have a great impact on the performance of the motor. The design of the blades must take into account the mechanics of liquid flow to achieve high-efficiency conversion.

End cap: The end cap is used to fix the blades and rotor to prevent liquid leakage. The oil holes and oil passages on the end cover ensure the smooth flow of hydraulic oil.

Seals: Seals include O-rings, packings, etc., which are used to prevent hydraulic oil leakage and ensure the normal operation of the motor.

— Performance characteristics of hydraulic vane motors

The vane motor has many characteristics. As a kind of hydraulic transmission device, the hydraulic vane motor has these characteristics reflected in our daily life applications.

1. High efficiency: Hydraulic vane motors have high mechanical efficiency and can convert hydraulic energy into mechanical energy with less loss.

2. Wide speed regulation range: The hydraulic vane motor has a wide speed regulation range and can meet the needs of different working conditions.

3. High torque: Hydraulic vane motors have high torque at low speeds and are suitable for heavy-load starting and low-speed operation.

4. Good reversal performance: The hydraulic vane motor has good reversal performance and can switch between forward and reverse rotation to meet different working requirements.

5. High reliability: The hydraulic vane motor has a simple structure, reliable operation, and is suitable for long-term continuous operation.

— Application fields of hydraulic vane motors

Upper blade motors may be used in engineering machinery, automobile manufacturing, aerospace, petrochemical and other industries. For example, in engineering machinery, hydraulic vane motors can be used to drive hydraulic cylinders, hydraulic cranes and other equipment; in the field of automobile manufacturing, hydraulic vane motors can be used in key processes such as engine assembly lines and body welding lines.

As an important hydraulic transmission device, hydraulic vane motors play a key role in various industries due to their excellent performance and wide application prospects. Understanding its working principle and performance characteristics will help us better apply hydraulic vane motors and provide efficient and reliable driving force for various projects.

— Maintenance and maintenance of hydraulic vane motor

Routine maintenance and upkeep play a big role in the normal operation and durability of the motor, so this step is essential.

1. Regularly check the quality and quantity of hydraulic oil. If the hydraulic oil becomes contaminated or deteriorates, it should be replaced in time. At the same time, ensure that the amount of hydraulic oil is sufficient to avoid poor lubrication or insufficient cooling due to lack of oil.

2. Regularly clean the internal parts of the hydraulic vane motor, including the rotor, blades, casing, etc. Use appropriate cleaning agents when cleaning to avoid corrosion or damage to parts.

3. Check whether the seal is aged or damaged. If there is any problem, replace it in time. At the same time, ensure that the seals are installed correctly to prevent poor sealing or leakage due to improper installation.

4. Regularly check whether the working pressure and flow rate of the hydraulic vane motor are normal. If an abnormality is found, the fault should be eliminated in time to ensure the normal operation of the motor.

5. For hydraulic vane motors that have not been used for a long time, regular operation inspections should be carried out to prevent poor lubrication or corrosion caused by long-term parking.

Hydraulic vane pumps have wide application prospects and important value. If we can understand more working principles, characteristics and maintenance knowledge during use, it will help us obtain better performance when using the motor. It also improves efficiency and saves time and money.

The hydraulic motors sold by poocca are all sold at factory prices, providing customers with products from the source factory, which are guaranteed. The price will be more favorable than that of ordinary suppliers, and the delivery time will also be advantageous. , welcome to send us your needs and contact poocca to provide you with high-quality, affordable motor products.

Post time: Jan-25-2024