Hydraulic piston pumps are the backbone of hydraulic systems used in various industries. However, the continuous wear and tear of these pumps over time result in the need for spare parts to keep them functioning correctly.

Table of Contents

1.Introduction

2.Types of Hydraulic Piston Pumps

3.Common Spare Parts for Hydraulic Piston Pumps

4.Pistons and Piston Rings

5.Valves and Valve Plates

6.Bearings and Bushings

7.Shaft Seals and O-Rings

8.Gaskets and Seals

9.Filter Elements

1. Introduction

Hydraulic piston pumps are widely used in heavy-duty machinery such as construction equipment, mining machinery, and agriculture equipment. These pumps use a reciprocating piston to generate hydraulic pressure, which is then used to power hydraulic cylinders, motors, and other hydraulic components.

Like any mechanical device, hydraulic piston pumps experience wear and tear over time, and their parts require replacement. Proper maintenance and the use of genuine spare parts can help prevent breakdowns, reduce downtime, and extend the life of the pump.

In the following sections, we will discuss the essential spare parts for hydraulic piston pumps and their functions.

2. Types of Hydraulic Piston Pumps

Hydraulic piston pumps are broadly classified into two types based on their construction – axial piston pumps and radial piston pumps.

Axial piston pumps have pistons that move parallel to the pump’s axis, generating hydraulic pressure. They are commonly used in mobile and industrial applications, where high pressure and efficiency are required.

Radial piston pumps have pistons that move radially outward from the pump’s center, generating hydraulic pressure. They are primarily used in high-pressure applications such as hydrostatic drives, presses, and machine tools.

3. Common Spare Parts for Hydraulic Piston Pumps

The following are the essential spare parts for hydraulic piston pumps that need regular maintenance and replacement:

4. Pistons and Piston Rings

Pistons and piston rings are critical components of hydraulic piston pumps, responsible for generating hydraulic pressure. Pistons are cylindrical or tapered, and they move back and forth inside the pump’s cylinder to displace fluid. Piston rings are mounted on the piston’s circumference to seal the space between the piston and cylinder, preventing fluid leakage.

5. Valves and Valve Plates

Valves and valve plates control the flow of hydraulic fluid into and out of the pump’s cylinder. They play a crucial role in regulating the pump’s pressure and ensuring its smooth operation.

6. Bearings and Bushings

Bearings and bushings are used to support and guide the pump’s rotating and reciprocating components. They help reduce friction, wear and prevent damage to the pump’s shaft and other critical components.

7. Shaft Seals and O-Rings

Shaft seals and O-rings are used to seal the gaps between the pump’s moving parts and the stationary parts. They prevent fluid leakage and contamination, ensuring the pump’s efficient operation.

8. Gaskets and Seals

Gaskets and seals are used to seal the pump’s housing and prevent fluid leakage. They play a crucial role in maintaining the pump’s pressure and preventing contamination.

9. Filter Elements

Filter elements are used to remove contaminants such as dirt, debris, and metal particles from the hydraulic fluid. They prevent the pump’s components from.

Conclusion

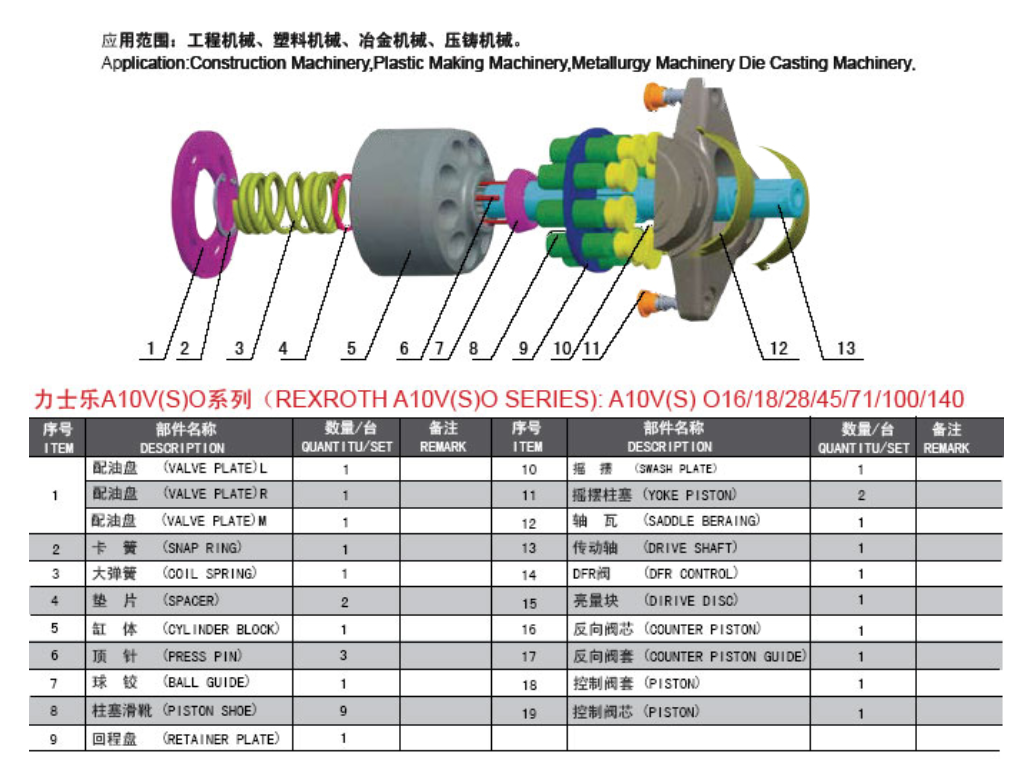

The accessories of the piston pump include:

(VALVE PLATE(L R M),(SNAP RING),(COIL SPRING),(SPACER),(CYLINDER BLOCK),(PRESS PIN),(BALL GUIDE),(PISTON SHOE),(RETAINER PLATE),(SWASH PLATE),(YOKE PISTON),(SADDLE BERAING),(DRIVE SHAFT),(DFR CONTROL),(DIRIVE DISC),(COUNTER PISTON),(COUNTER PISTON GUIDE),(PISTON),(PISTOW)

Post time: Apr-28-2023