Hydraulic systems are widely used in various industrial applications, and they rely on a number of different components to function effectively. One of the most important of these components is the hydraulic solenoid valve.

The Function of Hydraulic Solenoid Valve

Hydraulic solenoid valves play a vital role in controlling the flow of fluids in hydraulic systems. They are electromagnetic devices that are used to regulate the opening and closing of fluid ports in a hydraulic system.

Table of Contents

Introduction

What is a Hydraulic Solenoid Valve?

Types of Hydraulic Solenoid Valves

2-Way Solenoid Valve

3-Way Solenoid Valve

4-Way Solenoid Valve

FAQs

1. Introduction

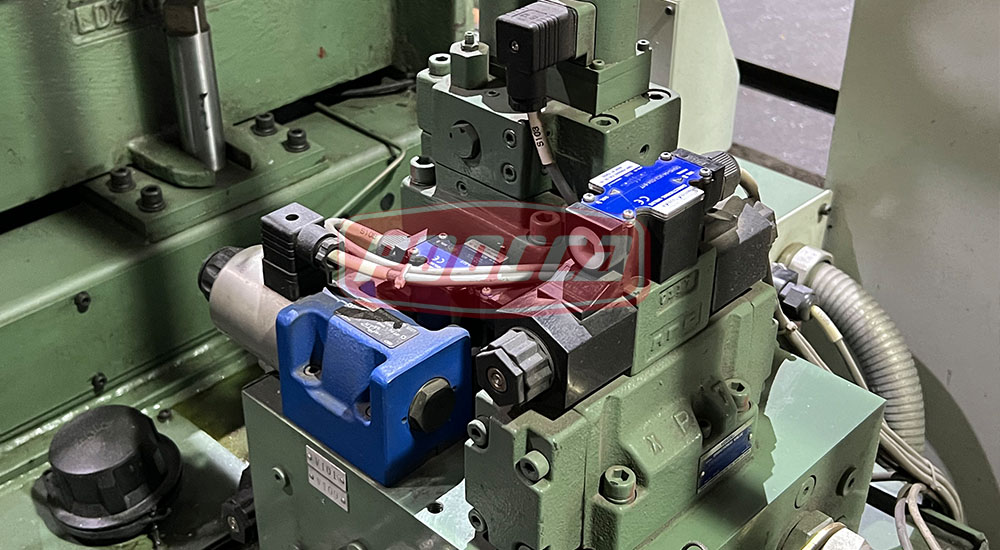

Hydraulic systems are widely used in various industrial applications to transmit power and control machinery. The hydraulic system consists of various components, including pumps, valves, actuators, and hydraulic fluid. The solenoid valve is one of the essential components of the hydraulic system. It is an electromechanical device that regulates the flow of hydraulic fluid through a control circuit.

2. What is a Hydraulic Solenoid Valve?

A hydraulic solenoid valve is an electro-mechanical valve that controls the flow of fluid through a hydraulic system. It has an electromagnetic coil that generates a magnetic field when an electric current is passed through it. This magnetic field attracts a plunger, which opens or closes the valve, controlling the flow of fluid.

3. Types of Hydraulic Solenoid Valves

Hydraulic solenoid valves are available in different types, including 2-way, 3-way, 4-way, and 5-way valves. Each type of valve is designed for a specific application and has its own unique characteristics.

3.1 2-Way Solenoid Valve

A 2-way solenoid valve is a type of valve that has two ports – an inlet and an outlet. When the solenoid is energized, the plunger opens the valve, allowing fluid to flow from the inlet to the outlet. When the solenoid is de-energized, the plunger closes the valve, stopping the flow of fluid.

3.2 3-Way Solenoid Valve

A 3-way solenoid valve is a type of valve that has three ports – an inlet, an outlet, and a exhaust port. When the solenoid is energized, the valve opens, allowing fluid to flow from the inlet to the outlet. At the same time, the exhaust port is opened, allowing any fluid that was previously in the outlet to escape. When the solenoid is de-energized, the valve closes, stopping the flow of fluid and sealing the exhaust port.

3.3 4-Way Solenoid Valve

A 4-way solenoid valve is a type of valve that has four ports – two inlets and two outlets. It is used to control the flow of fluid in a hydraulic system by diverting it from one circuit to another. When the solenoid is energized, the valve opens, allowing fluid to flow from one inlet to one outlet. At the same time, the other inlet is connected to the other outlet. When the solenoid is de-energized, the valve closes, stopping the flow of fluid and changing the

FAQs

- What is the function of a hydraulic solenoid valve?

- A hydraulic solenoid valve is responsible for controlling the flow of hydraulic fluid within a system.

- What are the different types of hydraulic solenoid valves?

- The different types of hydraulic solenoid valves include directional control valves, pressure control valves, and flow control valves.

- What industries use hydraulic solenoid valves?

- Hydraulic solenoid valves are used in industries such as manufacturing, construction, mining, and agriculture.

- What are the advantages of using hydraulic solenoid valves?

- Hydraulic solenoid valves offer precise control, high reliability, and long service life.

- How do you troubleshoot a malfunctioning hydraulic solenoid valve?

- Common problems with hydraulic solenoid valves include clogging, leakage, and valve sticking. Troubleshooting involves inspecting the valve for damage or debris, and cleaning or replacing damaged components.

Access All Amazing Prompts: https://www.pooccahydraulic.com/

Post time: Apr-18-2023