Gear pumps are widely used in various industrial and commercial applications, including hydraulic systems, lubrication systems, and fuel delivery systems. To ensure its reliability and performance, the POOCCA hydraulic gear pump has undergone various tests, including three coordinate testing.

What is Three Coordinate Testing of Gear Pump?

Three-coordinate testing is a method of measuring the geometric accuracy and surface finish of gear pumps. This testing method involves measuring three parameters of the gear pump – the radial runout, axial runout, and perpendicularity between the gear and shaft axis. The radial runout is the deviation of the gear center from the true geometric center, while the axial runout is the deviation of the shaft centerline from the true geometric center. Perpendicularity, on the other hand, is the angle between the gear and shaft axis.

Why is Three Coordinate Testing Important?

Three-coordinate testing is crucial in ensuring the optimal performance and longevity of gear pumps. The test results can help identify any deviations from the desired geometric accuracy and surface finish of the gear pump, which can affect its efficiency and lifespan. By identifying these issues, necessary adjustments can be made to improve the accuracy and performance of the gear pump.

Testing Process

The three-coordinate testing of gear pumps involves several steps, including the following:

Step 1: Preparations

The first step in three-coordinate testing is to prepare the gear pump for testing. This involves cleaning the pump and ensuring that it is in good condition for testing.

Step 2: Fixturing

After preparing the gear pump, it is then fixed onto a test fixture. The fixture holds the pump in place and ensures that it is stable during testing.

Step 3: Calibration

Before the actual testing, the measurement system is calibrated to ensure accuracy and precision. This involves measuring a known standard and comparing the results with the expected values.

Step 4: Testing

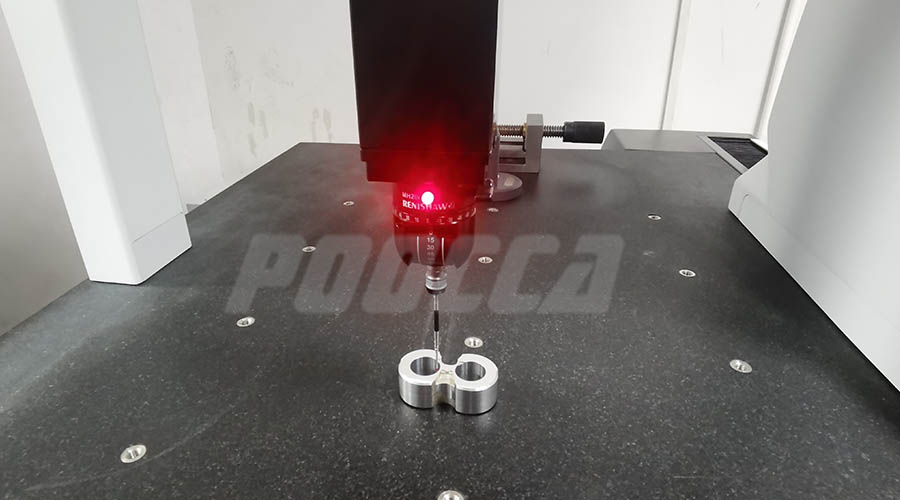

The actual testing involves measuring the three parameters of the gear pump – the radial runout, axial runout, and perpendicularity. This is done using a coordinate measuring machine (CMM), which takes precise measurements of the gear pump.

Step 5: Analysis

After completing the measurements, the data is analyzed to determine if the gear pump meets the required specifications. Any deviations from the desired values are identified, and corrective measures are taken to improve the accuracy and performance of the gear pump.

Benefits of Three Coordinate Testing

There are several benefits of three-coordinate testing of gear pumps, including the following:

Improved Quality

Three-coordinate testing can help identify any issues with the gear pump’s geometry and surface finish, which can affect its performance and longevity. By identifying these issues, manufacturers can make necessary adjustments to improve the quality and reliability of gear pumps.

Increased Efficiency

Accurate measurement of the gear pump’s geometry and surface finish can help improve its efficiency by reducing friction, wear, and energy consumption. This can lead to significant cost savings for industries that use gear pumps.

Compliance with Industry Standards

Three-coordinate testing is often required by industry standards and regulations, such as ISO 1328-1:2013 and AGMA 2000-A88. Poocca adheres to these standards to ensure that gear pumps meet the required specifications and can be safely used in various applications.

Conclusion

Three-coordinate testing is a crucial step in ensuring the optimal performance and longevity of gear pumps. This testing method can help identify any issues with the gear pump’s geometry and surface finish, which can affect its efficiency and lifespan.

All products in POOCCA manufacture undergo a series of tests and can only be shipped to customers after passing the tests to ensure that the products they receive are of high quality.

Post time: Apr-20-2023