Rexroth hydraulic pumps have become the cornerstone of fluid power and industrial automation. Renowned for their precision, reliability and cutting-edge technology, Rexroth hydraulic pumps play a key role in a variety of applications across industries. This article delves into the complexity of Rexroth hydraulic pumps, exploring their design, functionality and their impact on different areas.

History and Heritage:

To understand the importance of Rexroth hydraulic pumps, one must trace their roots. Founded by Robert Bosch in 1795, Bosch Rexroth has been a pioneer in hydraulic systems, consistently setting industry standards. Hydraulic pumps manufactured by Rexroth have evolved over the years to incorporate technological advancements to meet the growing needs of modern industry.

Design and Engineering:

Rexroth hydraulic pumps are characterized by their innovative design and engineering. These pumps use state-of-the-art technologies such as Computational Fluid Dynamics (CFD) and precision machining to deliver optimal performance. The design focuses on efficiency, durability and adaptability to different working conditions.

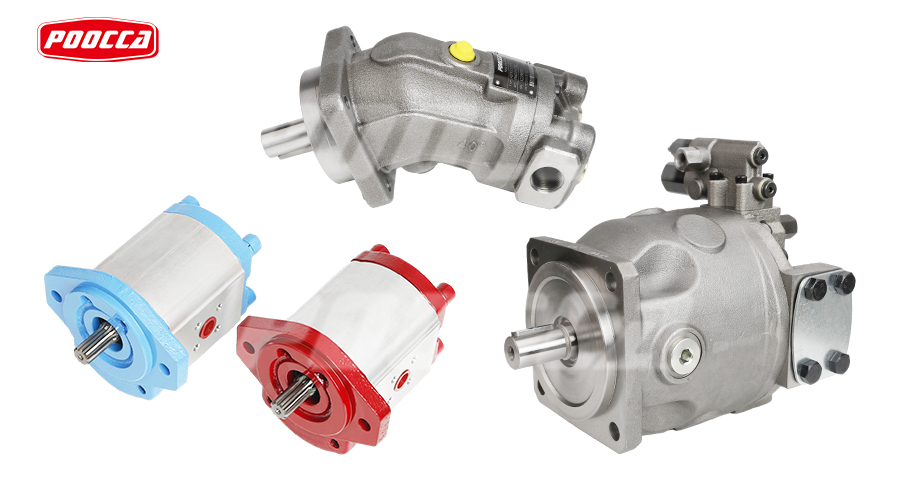

Hydraulic pump range:

Rexroth offers a full range of hydraulic pumps to meet the needs of a variety of applications. From axial piston pumps to vane and radial piston pumps, each type is engineered to meet specific requirements. The versatility of Rexroth hydraulic pumps makes them suitable for applications in agriculture, construction, manufacturing and more.

Efficiency and performance:

One of the key features of Rexroth hydraulic pumps is their high efficiency and outstanding performance. These pumps are designed to minimize energy losses, thereby saving industry costs. Its operational precision ensures consistent and reliable performance, even in challenging environments.

Industry applications:

Rexroth hydraulic pumps are widely used in various industries. In agriculture, they power tractors and machinery, increasing productivity. During construction, these pumps drive heavy equipment, ensuring efficient operation. Manufacturing industries rely on the precision and reliability of Rexroth hydraulic pumps in a variety of processes.

IoT integration and smart features:

In line with the Industry 4.0 era, Rexroth hydraulic pumps are equipped with smart features and IoT integration. This enables real-time monitoring, predictive maintenance and remote control to optimize pump efficiency and service life. The incorporation of digital technologies improves overall performance and reduces downtime.

Environmental considerations:

Rexroth hydraulic pumps are designed with environmental sustainability in mind. The focus on energy efficiency not only benefits industries in reducing operating costs but is also consistent with global efforts to reduce carbon footprints. These pumps meet strict environmental standards, making them a responsible choice for industries aiming to minimize their impact.

Research and development:

Bosch Rexroth’s commitment to innovation is reflected in its ongoing research and development efforts. Continuous improvements in materials, design and manufacturing processes ensure that Rexroth hydraulic pumps remain at the forefront of hydraulic technology. This dedication to innovation has made Rexroth a leader in the hydraulic pump industry.

Product Category:

poocca sells hydraulic pumps that can replace Rexroth plunger pumps, gear pumps, motors, hydraulic valves, etc. Among them,

the piston pump series: A10VO, A22VO, A4FO, A11VO, A8VO…

Gear pump: single pump AZPF, PGH, 1PF2G, AZPB, AZPN, AZPW. Double gear pump AZPFF, triple gear pump AZPFFF…

Motor: AZMF, A2FM, A6VM, A6VE….

how to buy:

Poocca is a powerful hydraulic enterprise integrating design, R&D, manufacturing, sales and maintenance. It sells various hydraulic pumps with more than 1,600 types. Welcome to send us the hydraulic products you need, and Poocca will contact you as soon as possible. connect.

Post time: Jan-06-2024