In the world of hydraulic systems, choosing the right pump depends on several factors, such as hydraulic oil compatibility, operating pressure, application speed and flow requirements. Among the many options available, two standout choices are piston pumps and gear pumps. This article will provide an in-depth look at how each method works, its applications, and its benefits.

Learn about hydraulic piston pumps

Piston pumps use a piston that moves back and forth within a cylinder to create the force needed to move fluid. This movement creates pressure that forces the fluid through the pump and out to the desired location. Piston pumps are typically used in high pressure applications and can handle a wide range of viscosities.

A rotary pump, on the other hand, uses a rotating element, such as a rotor or impeller, to create the force needed to move fluid. This movement creates suction that draws fluid into the pump and then expels it to the desired location. Rotary pumps are typically used in low pressure applications and are best suited for handling low viscosity fluids.

Generally speaking, piston pumps are more efficient at generating high pressures, while rotary pumps are better suited for handling low viscosity fluids. The type of pump best suited for a particular application depends on the specific requirements of that application.

How do they work?

The piston pump uses a positive displacement mechanism. As the piston reciprocates within the cylinder, it draws in hydraulic fluid during the retraction phase and then pushes it out during the extension phase, creating a fluid flow.

Advantages and common applications

Piston pumps are distinguished by their ability to withstand extremely high pressure ratings, making them the ideal power source for heavy equipment such as lifts, presses and excavators. In addition, their complex internal designs often allow fine-tuning of displacement per revolution to meet different operating requirements.

Precautions

Despite their superior performance, it’s worth noting that piston pumps typically have a higher price tag than similar pumps such as gear pumps. However, the greater efficiency and durability they offer often justifies the initial investment, especially for industries that rely on sustained output.

In summary, while the upfront cost of a hydraulic piston pump may seem daunting, its unparalleled performance and adaptability make it an indispensable asset in demanding hydraulic applications, ensuring optimal functionality and longevity of your hydraulic system.

Explore Hydraulic Gear Pumps

Now, let’s delve into the realm of hydraulic gear pumps. These pumps use a simple yet effective mechanism, including gears or cogs, to move fluid within a hydraulic system. The closely spaced gears create suction as they draw in liquid and then expel it. Depending on the application, gear pumps can be equipped with internal or external gears.

Operation Mechanism

Gear pumps, like piston pumps, belong to the category of positive displacement pumps. However, unlike piston pumps, gear pumps maintain a fixed displacement configuration. This means that in order to regulate fluid displacement, additional pumps or valves are required.

Advantages and common applications

Gear pumps are known for their reliability and durability, as long as they are maintained regularly. One of their main advantages over piston pumps is that they require relatively low maintenance and are more economically priced. However, it is worth noting that gear pumps typically operate within a maximum pressure range of around 3000 PSI. While this is sufficient for many applications, it may not be enough to power large industrial equipment such as presses.

scenes to be used

These pumps are widely used where low pressure operation is common, especially when handling high viscosity liquids. Industries such as food and beverage, pulp and paper, and petroleum and chemicals often rely on gear pumps for their fluid transfer needs.

Salient features of plunger pumps

The fundamental difference between gear pumps and piston pumps lies in their design and operating principles. While both are used to generate mechanical power from hydraulic fluid, piston pumps rely on the movement of pistons to facilitate fluid transfer within the pump valve, while gear pumps do this through the movement of g ears.

In summary, hydraulic gear pumps provide a cost-effective and reliable solution for a variety of low-pressure hydraulic applications, making them an indispensable component in various industries. Although they have fixed displacement and limited pressure capabilities, their simplicity, durability, and suitability for specific tasks make them valuable assets in fluid handling systems.

Do you need a pIston pump or a gear pump?

You can purchase the hydraulic piston pump or gear pump you need according to your mechanical application.

Gear pumps are suitable for low pressure applications (35 to 200 bar or 507 to 2900 PSI), then piston pumps are the more efficient option for high pressure applications. If you are now looking for a pump with high efficiency, a piston pump is also a better choice.

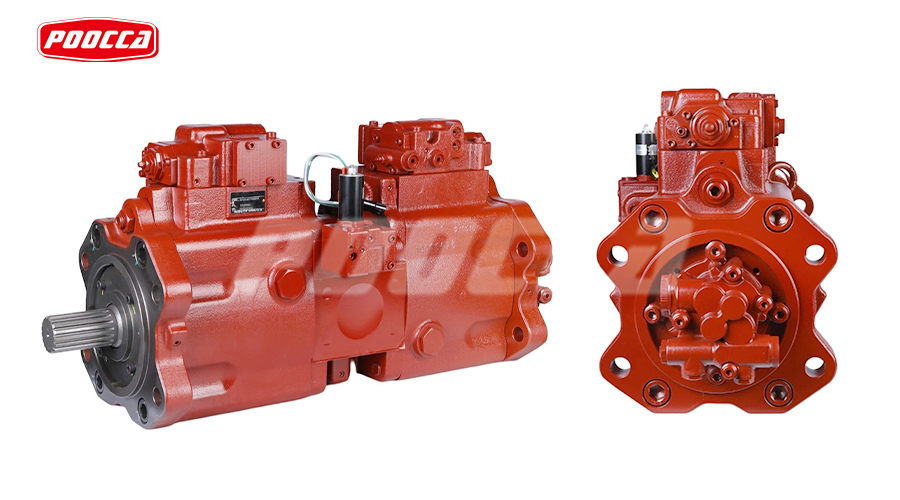

Buy hydraulic pump from poocca hydraulic manufacturer

We have 20+ experience specializing in gear pumps, piston pumps, vane pumps, motors, hydraulic valves, all pumps manufactured by POOCCA are made in-house in the USA and guaranteed to OEM specifications.

If you’re looking for a cost-effective and timely pump replacement solution, you’re looking for us. Contact us today for help selecting the right pump for your application, or to request a product quote.

Post time: Mar-23-2024