Piston Pumps PVM Variable Displacement

|

Model Series |

Max Speed “E”* (rpm) |

Max Speed “M”*(rpm) |

Min Speed (rpm) |

Nominal Pressure (bar) |

Peak Pressure (bar) ** |

Inertia (kg-cm2) |

| PVM018 | 1800 | 2800 | 0 | 315 | 350 | 11.8 |

| PVM020 | 1800 | 2800 | 0 | 230 | 280 | 11.8 |

| PVM045 | 1800 | 2600 | 0 | 315 | 350 | 36.2 |

| PVM050 | 1800 | 2600 | 0 | 230 | 280 | 33.9 |

| PVM057 | 1800 | 2500 | 0 | 315 | 350 | 51.6 |

| PVM063 | 1800 | 2500 | 0 | 230 | 280 | 50.5 |

| PVM074 | 1800 | 2400 | 0 | 315 | 350 | 78.1 |

| PVM081 | 1800 | 2400 | 0 | 230 | 280 | 72.7 |

| PVM098 | 1800 | 2200 | 0 | 315 | 350 | 131.6 |

| PVM106 | 1800 | 2200 | 0 | 230 | 280 | 122.7 |

| PVM131 | 1800 | 2000 | 0 | 315 | 350 | 213.5 |

| PVM141 | 1800 | 2000 | 0 | 230 | 280 | 209.7 |

• Bell shaped housing contains fluid borne sound and reduces operator fatigue.

• Standard adjustable maximum volume screw and gage ports give the ultimate in flexibility to the engineer or service technician

• High overall efficiency reduces operating costs

• Robust shaft bearings extends operating life and lowers maintenance costs

• Multiple port type and locations aid in flexibility of machine design

• Very low pressure ripple reduces shock in the system resulting in fewer leaks

The M Series also contains a strong proven rotating group allowing the pumps to handle

pressures to 315 bar (4568 psi) continuous with less maintenance cost. M Series pumps operate at a level of quietness that exceeds the requirements of today’s demanding work conditions. High-load bearings and a stiff drive shaft help provide very long life at rated industrial conditions, reducing operating costs and extending operating life.

M Series pumps feature a saddle-type yoke with steel-backed polymer bearings. A single control piston reduces loading on the yoke, resulting in reduced pump size which allows installation in tighter locations.

The pumps feature a unique three-piece envelope (flange, housing and valve block) specifically created for low fluid-borne and structure-borne noise levels. Another pump feature – a bimetal timing plate – improves pump filling characteristics which, in turn, reduce fluid-borne noise and extend pump life.

M Series pumps reduce, or in some cases remove,the need for damping barriers between the noise source and the operator. This saves money on the installed cost of the system while improving customer comfort. An adjustable maximum stop provides a means of tuning flow to your system, while gauge ports allow monitoring of inlet and outlet conditions.

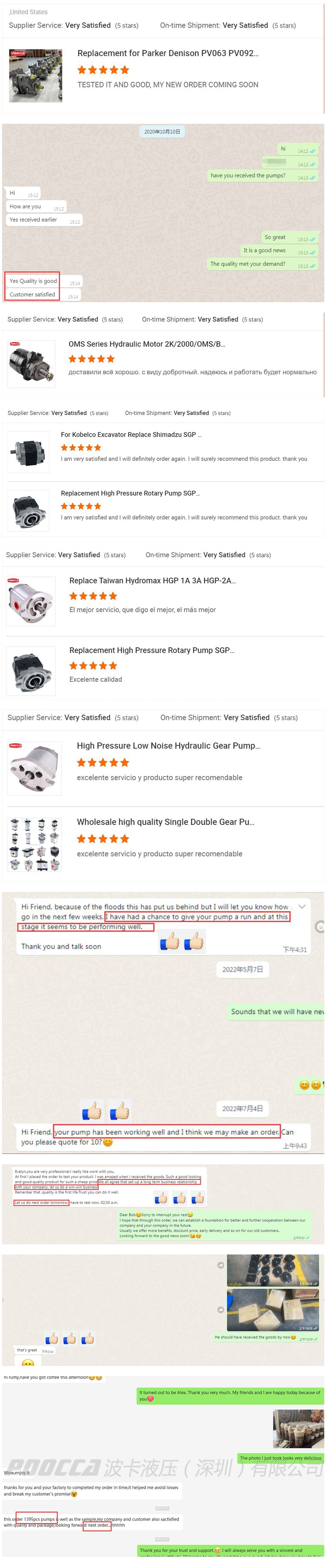

As a competent manufacturer of diversified Hydraulic Pumps, we are thriving across the globe and we are happy to share the overwhelming positive feedback we have received from satisfied customers across the globe. Our products have won accolades for their superior quality and performance. Consistent positive reviews reflect the trust and satisfaction customers experience after making a purchase.

Join our customers and experience the excellence that sets us apart. Your trust is our motivation and we look forward to exceeding your expectations with our POOCCA hydraulic pump solutions.